Industry 4.0 represents a radical change in the way factories and production processes are designed and operated. It is a convergence of digital, physical and biological technologies that are transforming the way companies manufacture products and deliver services. This industrial revolution is driven by the interconnection of cybernetic systems, intelligent automation and the collection and analysis of large volumes of data in real time.

Characteristics of Industry 4.0

The essential features of Industry 4.0 include the digitalization of production processes, the integration of systems and machines, the mass customization of products, flexibility in production and intelligent automation. This approach enables factories to become more agile, efficient, sustainable and adaptable to market demands.

What are the pillars of Industry 4.0?

The fundamental pillars of Industry 4.0 are interconnection, information transparency, autonomous decision-making and computer-aided manufacturing. Interconnection enables communication between machines, systems and devices, creating an intelligent production network. Information transparency ensures access to data throughout the value chain, facilitating decision-making based on accurate, real-time information. Autonomous decision-making enables machines to take corrective action without human intervention, increasing efficiency and productivity. Finally, computer-aided manufacturing uses advanced technologies such as 3D printing and robotics to optimize production processes.

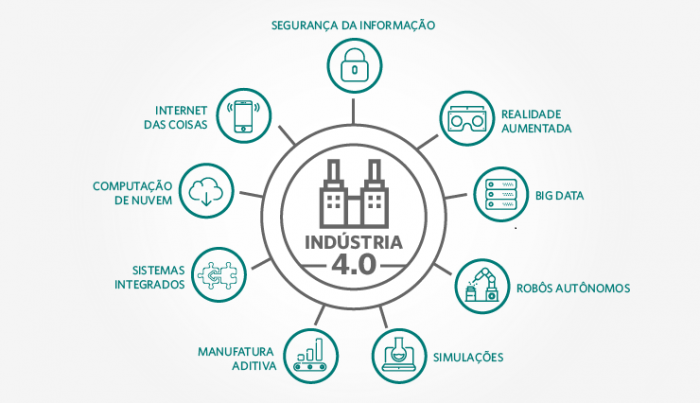

Main technologies of Industry 4.0

Key technologies of Industry 4.0 include Internet of Things (IoT), artificial intelligence (AI), cloud computing, big data analytics, advanced robotics, additive manufacturing (3D printing), augmented reality and cybersecurity. These technologies are being widely adopted by businesses to increase efficiency, reduce costs, improve the quality of products and services, and drive innovation.

Industry 4.0 Scenario in Brazil Today

In Brazil, Industry 4.0 is still in its early stages, but it is gaining momentum as more companies recognize the benefits of digitalization and automation. The Brazilian government is encouraging the adoption of 4.0 technologies through incentive policies and training programs. However, there are still challenges to be overcome, such as limited digital infrastructure, lack of skilled labor, and cultural resistance to change.

Challenges and expectations of Industry 4.0

The challenges of Industry 4.0 include adapting to new technologies, system interoperability, cybersecurity and organizational resilience. Companies need to invest in training and upskilling their staff, update their technological infrastructure and review their business models to take full advantage of the opportunities offered by Industry 4.0. Expectations include greater operational efficiency, cost reduction, increased productivity and the development of more personalized products.

Impact of Industry 4.0 on people management

Industry 4.0 is transforming the way companies manage their workforce, requiring digital skills, adaptability and multidisciplinary collaboration. Companies need to invest in training and development of their employees to prepare them for the challenges and opportunities of Industry 4.0. In addition, new leadership models and organizational culture are emerging to support the transition to a digitalized and data-driven economy.

The future of employment in Industry 4.0

While Industry 4.0 may automate some tasks, it will also create new job opportunities in areas such as data analysis, programming intelligent systems, and maintaining advanced technologies. Companies will need professionals with technical skills, creativity, problem-solving skills, and critical thinking to take full advantage of the opportunities offered by Industry 4.0.

Consequences of Industry 4.0 in companies

Companies that embrace Industry 4.0 can reap a range of benefits, including increased operational efficiency, reduced costs, improved product and service quality, increased competitiveness in the global marketplace, and the creation of new business opportunities. However, they will also face challenges, such as the need to invest in new technologies, upgrade their skills and competencies, and face competition from new digital competitors. Ultimately, Industry 4.0 is transforming the way companies operate, create value, and engage with their customers, and those that successfully adapt to this new reality will be well-positioned to thrive in the future.

Talk to Software to learn more about Industry 4.0 together with a specialist, via email comercial@software.com.br.

See more about Industry 4.0 at Software.com.br.

5 min read

5 min read